|

|

Home

Tools

Drilling and Fixing

Putting Things Up

Repairs/Maintenance

Plumbing

Electrics

Woodwork

Decorating a Room

Tiling

Safety & Security

Saving Energy

Health&Safety

Disclaimer

Contact

Advertising

Useful Links

Site Map

| Types of wood | ||||||||||||||

There are loads of different types of wood for use on different jobs. |

||||||||||||||

| " The Forest Stewardship Council enables you to buy forest products of all kinds with confidence that you are not contributing to global forest destruction." | ||||||||||||||

Different types of wood Soft wood is used in a huge range of general constructional jobs. In the UK It's usually pine or spruce. It's cheap and very easy to work with. Although some care is required to avoid it splitting when nailing, screwing into, sawing or drilling. |

||||||||||||||

Sawn treated -quite roughly presented this is used for outdoor use and is pressure treated with preservative to help prevent rotting. Used in fencing a lot. You can usually tell it's treated by it's slightly odd colour usually a browny or greeny tinge to it depending on the color of preservative. |

|

|||||||||||||

Hardwood is much more expensive than soft wood and is used in more quality joinery jobs, expensive flooring, or outside areas which are exposed to the weather like front doors. It's often used on expensive window frames as it looks great and last for years. On floors it's very hard wearing. |

||||||||||||||

|

||||||||||||||

Wooden sheetingVarious types are available and all usually come in thickness' of 4 mm, 6mm. 9mm. 12 mm. 15 mm. 18 mm. 24 mm. A large sheet will be 8 feet x 4 feet which will be the size you get from a builders merchant. DIY stores will usually supply smaller sizes as well. | ||||||||||||||

|

||||||||||||||

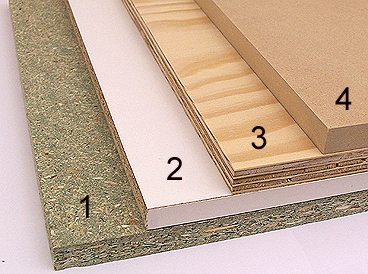

1 chipboard 3 Plywood 4 MDF |

||||||||||||||

MDF (medium density fibre board) very popular these days. It's made from powdered wood which is bonding with glue and compressed to form the sheets. Used widely for interior projects especially cupboards and shelving. It gets' very dusty when sanding it so you'll need to where a dust mask. It is very absorbant. Usually needs 4 coats of paint to get a nice finish on it but it does come up very nicely. NB you can now buy MDF with a wood veneer like cherry, oak, etc. These are quite expensive but do look great. |

||||||||||||||

Tip a lot of timber suppliers have cutting facilities. They use very large saws which cut lovely square edges very accurately. On shelving or cupboard projects it's well worth getting sheets cut down to your own requirements. It's a lot less hassle than struggling with large sheets especially if you have limited space. Make a cutting list of all you need then have it cut and delivered...easy! |

||||||||||||||

Chipboard Made similarly to MDF but from actual wood chips. Used widely by kitchen manufactures who cover it with a laminate. Also used widely for low cost flooring You can buy flooring packs in different sizes which come tongue and grooved which allows each section to slot together with the next before screwing or nailing down. If used for shelving It's fairly weak so needs well supported. It doesn't paint very well and the edges are quite rough. I rarely use it these days for shelving, though it is very cheap. |

||||||||||||||

Plywood This is made from thin laminates of wood glued together each layer at right angle to the grain of the other. It' very very strong but also quite flexible, especially if you get thinner sheets. It's used widely in the building industry as it's so strong. Used for things like boxing in, sub floors prior to tiling, and loads of other things. It's tougher to work with and the edges tend to fray a bit when sawn. It doesn't paint up very well. Best used where it's not seen. It's quite expensive, especially if you buy the most expensive, marine ply, which is very good quality and quite water proof. |

||||||||||||||

Conti board This is laminated chipboard available in white or various other colours and finishes. Used widely in kitchen carcases You can usually buy it in 6 feet lengths of various widths. Can be use for shelving but will need plenty of support. Inexpensive. |

||||||||||||||

Composite wood alternatives This type of wood is especilly useful in outside spaces. Composite wood products are a blend of powdered wood and powdered polyethylene. They are bonded together to form a strong weather reisitant product. Decking, cladding, fencing are readily made from these composites which come in a variety of colours and finishes. Some mimic traditional wood so you get the natural feel of wood, the plastic provides strength and durability. |

||||||||||||||